They make Australia a strong player in the global market. With more demand for biologics, making them locally can boost the Australian biopharmaceutical industry. This can lead to better reliability, lower costs, and stronger supply chains.

Key Takeaways

- CHO cells are crucial in biologics production, particularly in Australia.

- Local manufacturing of biologics can enhance supply chain reliability.

- The Australian biopharmaceutical industry is increasingly investing in CHO cell technologies.

- Understanding the role of CHO cell manufacturers can provide a competitive edge.

- Growing demand for biologics is driving innovation in local manufacturing capabilities.

- Investing in local CHO cell production can minimize costs and boost efficiency.

Overview of CHO Cells in Biologics Manufacturing

CHO cells, or Chinese Hamster Ovary cells, are key in biologics manufacturing. They can produce high-quality proteins well. This makes them important in Australia’s biotech and pharma sectors.

Definition and Importance of CHO Cells

CHO cells are used a lot in biotech for making biologics like antibodies and proteins. They’re good at adding important changes to proteins. This makes the proteins work better.

When we talk about CHO cell line biologics production, their role is clear. They help meet the need for more biologics.

Advantages of Using CHO Cells in Biologics

CHO cells have many benefits for biologics production:

- They grow well, allowing for more cells in one place.

- They can do complex changes to proteins, making them work right.

- They make proteins fast, which helps in making lots of them.

These points show why CHO cells are a top choice in the pharma world.

Applications in Biologics Production

CHO cells are used in many ways, from finding new drugs to making them on a big scale. They’re key in making many medicines. They also help Australia a lot in biologics production, making it a big player globally.

Market Landscape for Biologics in Australia

The biologics sector in Australia is growing fast. It’s all about innovation and quality. Around 400 companies are working on biologics, like drugs and therapies from living things. This helps both local and global projects, especially in australian cho cell biologics.

Current State of the Biologics Industry

The biologics industry is seeing a lot of investment in research. Companies are using biologics to find new treatments for hard diseases. They’re also using new technologies to make production better, which fits with the trend in commercial biologics manufacturing in Australia.

Key Players in the Australian Market

Companies like GlyTherix and Patheon show the variety in the sector. They mix local ideas with international skills, which is key for progress in biologics. Their work makes Australia a big player in the global biologics market.

Regulatory Framework for Biologics in Australia

The rules for making biologics in Australia are strict. The Therapeutic Goods Administration (TGA) makes sure products are safe and work well. This makes australian cho cell biologics reliable and builds trust in the industry.

Role of CHO Cells in Biologics Production

Chinese Hamster Ovary (CHO) cells are key in making biologics, especially monoclonal antibodies. They have special ways that make them great for research and production.

Mechanisms of CHO Cell Functionality

CHO cells can grow well in different conditions. This helps them make proteins efficiently. Glycosylation, a critical process, happens in these cells, making antibodies work better.

Examples of Biologics Produced with CHO Cells

Many medicines, like Rituximab and Trastuzumab, were made with CHO cells. This shows how important CHO cell biotech Australia is to the biologics market.

Comparison with Other Cell Lines in Biologics

CHO cells are better than other cells in many ways. They can grow a lot and make more products. This makes them leaders in biologics production, giving consistent results.

Identifying CHO Cell Manufacturers in Australia

The world of biologics is changing fast. Finding the right players is key to making production better. In Australia, strong cho cell manufacturers are leading the way. They help grow the biologics industry by innovating and working together.

Leading Manufacturers of Biologics in Australia

In Australia, Patheon and DSM Biologics are leaders in cho cell technology. They have top-notch facilities with the latest tech for quality production. Their work helps Australia shine on the global stage.

Research Institutions Utilizing CHO Cells

Universities and biotech firms are using CHO cells for research. They are crucial for advancing biologics science. This teamwork between schools and companies brings new discoveries and ideas.

Industry Partnerships and Collaborations

Companies are teaming up, showing a spirit of cooperation. For example, GlyTherix and GenScript ProBio are working together. Their partnership boosts Australia’s cho cell industry, creating a space for growth and progress.

Case Studies: Successful Use of CHO Cells

Recent advancements in biologics production show the big role of CHO cells, especially in Australia. They are great at making complex proteins. This has led to new biologics made with CHO cells. Looking at case studies, we see how CHO cells have changed how we make medicines.

Australian Biologics Companies Using CHO Technology

Many top Australian companies use CHO cell technology. They show how CHO cells can make effective medicines. By using this tech, they make their production better and more competitive.

Innovative Biologics Developed with CHO Cells

GlyTherix is a great example of CHO cell use. They made Miltuximab, a new treatment. This shows CHO cells can help create new medicines. It shows Australian companies can lead in making new treatments.

Lessons Learned from CHO Cell Applications

Many projects with CHO cells have taught us a lot. We’ve learned to improve culture conditions and solve problems. By learning from successes and failures, companies can make their work better.

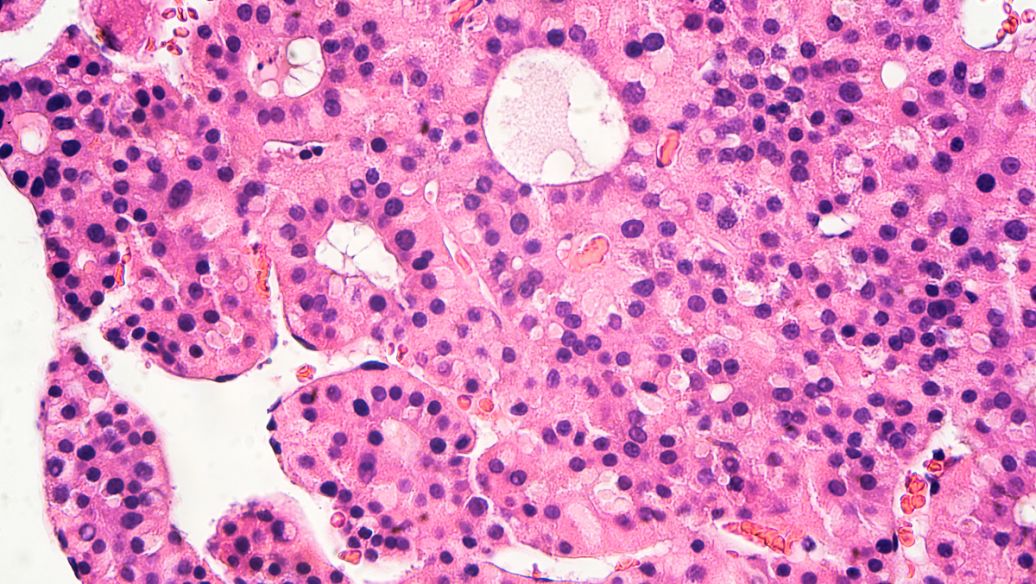

This picture is a display picture of cho cell.

Challenges and Limitations of CHO Cell Use

CHO cells are used in making biologics, but they come with challenges. Troubleshooting and planning can help overcome these issues. This section looks at common problems, regulatory hurdles, and the financial side of things.

Common Issues in CHO Cell Culture

CHO cell culture faces several hurdles. These affect how well cells grow and how much product they make. Here are some of the main issues:

- Contamination: Bacteria can stop cells from growing and spoil the product.

- Cell Line Stability: Changes in cell lines can cause problems with consistency.

- Productivity Inconsistencies: Changes in how much product is made can make scaling up hard.

Regulatory Challenges in Biologics Manufacturing

Following strict rules is a big challenge in making biologics. These rules need a lot of resources and knowledge. For small companies, it can be hard to meet these standards.

This can slow down getting products to market. It also makes the production process more complicated.

Cost Considerations for Using CHO Cells

CHO cells are good at making lots of product, but they can be expensive. Here are some of the costs:

- Compliance Costs: Following rules can be very costly.

- Technology and Equipment: Buying the latest technology is a big expense.

- Skilled Personnel: Finding and training good people is expensive, especially for new companies.

Future Trends in CHO Cell Manufacturing

Biologics manufacturing is getting better, thanks to new technologies. These changes are making CHO cell use more efficient. Experts think we’ll see more uses and better results soon.

Emerging Technologies in Biologics

New tools like automated bioprocessing and advanced analytics are key. They make production smoother and cut down on mistakes. This means better products and faster work for companies.

Potential Developments in CHO Cell Research

Gene editing and synthetic biology are leading the way in CHO cell research. These could lead to more effective treatments and higher yields. Scientists are working hard to improve cell lines for better results.

Predictions for the Biologics Market in Australia

The Australian biologics market is set to grow, thanks to smart investments. Partnerships among companies will boost innovation and growth. Today’s efforts will help create a strong biologics sector in Australia.

Comparison of CHO Cell Manufacturers

In the world of biologics, picking the right CHO cell maker is key. It affects how well and how much you can make, and how much it costs. This part talks about what to look for in a CHO cell provider, including how well they do and what they charge.

Criteria for Choosing a CHO Cell Manufacturer

Choosing a CHO cell maker needs careful thought. Look at these important points:

- Technological Capabilities: Make sure they have the latest tech for growing cells.

- Experience: Check if they’ve made biologics before. Experience means they’re reliable.

- Compliance History: See if they follow rules well. This is key for making products that work.

- Service Offerings: Find out if they help you from start to finish. This makes things easier.

Performance Metrics of CHO Cell Providers

When comparing CHO cell makers, look at how they perform. Important things to check are:

- Batch Yield: This shows how much product you get from each batch. It affects costs.

- Turnaround Time: See how long it takes from start to finish. This helps plan your schedule.

- Regulatory Adherence: Check if they follow rules well. This makes getting products to market easier.

Cost vs. Quality: Making the Right Choice

It’s important to find a balance between cost and quality. Cheap options might look good but can be risky. High-quality makers might cost more upfront but can lead to better results and success. Choosing reliable CHO cell providers is a smart investment in the competitive biologics market.

Benefits of Local CHO Cell Manufacturers

Local CHO cell manufacturers bring many benefits to biologics production. They make the process more efficient and effective. This helps not just the production but also the whole Australian biotech scene.

Advantages of Sourcing Biologics Locally

There are several key advantages to choosing local suppliers for biologics manufacturing:

- Reduced lead times: Being close means orders are filled faster and market needs are met quicker.

- Enhanced quality control: Local makers can enforce strict quality checks more easily because they’re nearby.

- Lower shipping costs: Cutting down on shipping costs helps keep production costs down.

Impact on Supply Chain and Logistics

Having a strong local supply chain is key in today’s fast-changing world. Local biologics manufacturing has a big impact:

- Increased resilience: Making things locally reduces the risk of global supply chain problems.

- Faster adaptability: Local makers can quickly adjust to new rules and market trends.

- Streamlined logistics: Simplifying cross-border logistics cuts down on delays and makes things smoother.

Supporting the Australian Biotech Ecosystem

Investing in local CHO cell manufacturers boosts the Australian biotech sector. The benefits are clear:

- Encouraging innovation: A local industry fosters a great environment for research and development.

- Job creation: Local operations create jobs, helping the economy grow.

- Building partnerships: Working together with local businesses and research groups strengthens the scientific community.

Conclusion and Recommendations

CHO cell manufacturers in Australia play a key role in making biologics. They are known for their efficient protein production and ability to scale up. The market has many local makers who meet the needs of biologics while following rules.

Looking ahead, research should improve cell culture, gene editing, and follow rules better. Investing in new methods and technology is key. Working together can lead to better products and processes.

Knowing what local CHO cell makers do is important for the biologics field. Supporting Australian makers helps the supply chain and the biotech scene. This keeps Australia competitive and helps public health.

References and further readings:

1.Nguyen, M. (2025). Impact of S-sulfocysteine on Chinese hamster ovary cells (Doctoral dissertation, Technical University of Darmstadt).

Retrieved from https://tuprints.ulb.tu-darmstadt.de/27403/1/Dissertation_Melanie%20Nguyen_Final.pdf

2.Amaral, M. L., Song, Y., Baez-Becerra, C. T., & Cho, S. et al. (2025). Cell-type-specific transposable element demethylation and TAD remodeling in the aging mouse brain. bioRxiv.

https://www.biorxiv.org/content/10.1101/2025.04.21.648266v1

FAQ

What are CHO cells and why are they important in biologics manufacturing?

CHO (Chinese Hamster Ovary) cells are key in biotech for making biologics. This includes things like medicines and proteins. They’re important because they can do special steps after the protein is made.

How do CHO cells compare to other cell lines used in biologics production?

CHO cells stand out because they can grow a lot and make complex proteins well. This makes them great for making medicines on a big scale.

What is the current state of the biologics industry in Australia?

Australia’s biologics industry is growing fast. About 400 companies are working in this field. They’re making new medicines and doing local production.

Who are the key players in the Australian biologics market?

Big names in Australia include GlyTherix and Patheon. They show a mix of local and international work. This helps in making medicines with CHO cells.

What regulations govern CHO cell manufacturing in Australia?

The Therapeutic Goods Administration (TGA) sets rules for making medicines in Australia. They make sure the products are safe and work well.

What challenges do CHO cell manufacturers face in Australia?

Companies face issues like keeping cell lines stable and dealing with contamination. They also have to follow strict rules and manage costs while keeping quality high.

Are there any notable Australian companies utilizing CHO technology in their biologics production?

Yes, many Australian biotech firms use CHO cells for making medicines. For example, GlyTherix’s Miltuximab is a success story in this area.

What emerging technologies are influencing CHO cell manufacturing?

New tech like automated systems, advanced analytics, and gene editing are changing things. They make CHO cell work more efficient and effective.

How does local sourcing of biologics impact the Australian biotech ecosystem?

Making medicines locally cuts down on time, improves quality, and saves on shipping. It makes the supply chain stronger and helps the biotech sector grow.

What factors should companies consider when choosing a CHO cell manufacturer?

Look at the manufacturer’s tech, experience, and track record with rules. Also, consider what services they offer. This is key for working together well in making medicines.

Leo Bios

Hello, I’m Leo Bios. As an assistant lecturer, I teach cellular and

molecular biology to undergraduates at a regional US Midwest university. I started as a research tech in

a biotech startup over a decade ago, working on molecular diagnostic tools. This practical experience

fuels my teaching and writing, keeping me engaged in biology’s evolution.

Leave a Comment

Your email address will not be published. Required fields are marked *