Ever thought about how a small microplate can change science? The 96 well plate’s dimensions are key to many discoveries in labs around the world.

Knowing about microplate specs is vital for scientists. These tools have 96 wells in a small space, 127.76 x 85.48 mm. They help scientists do complex tests efficiently.

Each well is like a tiny lab, made with great care. The 96 well plate’s size lets it be used in many fields, from finding new drugs to studying genes.

Key Takeaways

- Standard 96 well plate dimensions are critical for experimental consistency

- Microplate specifications impact research outcomes significantly

- Well spacing and volume are key technical parameters

- Different bottom designs offer specialized research capabilities

- Precision in well dimensions enables high-throughput screening

Overview of 96 Well Plates

Scientific research needs precision, and 96 well plates are key. They change how we handle samples in labs. This makes experiments more efficient and accurate.

Definition and Purpose

A 96 well plate is a special microplate with 96 wells. It has 12 columns and 8 rows. Made from top-quality materials, it’s a versatile tool for many scientific studies.

Common Applications

- Cell culture research

- Biochemical assays

- High-throughput screening

- Colorimetric and fluorescence analysis

- Molecular biology experiments

Importance of Dimensions

Knowing the dimensions of 96 well plates is key. They fit with lab equipment and give consistent results. There are different types of plates:

- Clear flat bottom plates: Great for optical tests

- V-bottom plates: Best for collecting samples

- U-bottom plates: For specific lab protocols

“Precision in plate design translates to precision in scientific discovery.” – Laboratory Research Quarterly

The standard size of 96 well plates is 127.76 mm by 85.48 mm. This size is used in many scientific fields.

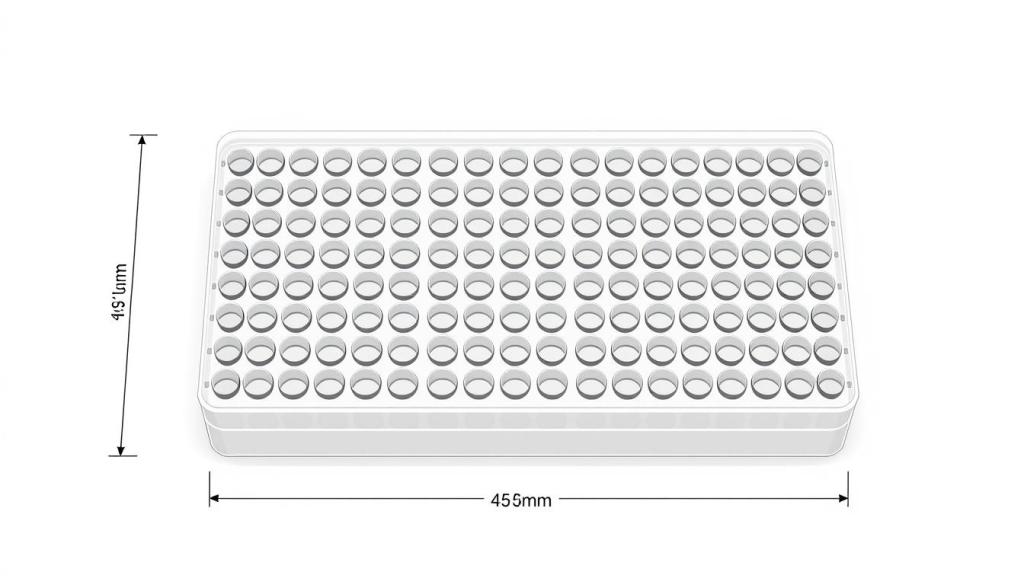

Standard Dimensions of 96 Well Plates

Microplate specifications are key for precise and consistent lab research. Knowing the details of 96 well plates helps scientists improve their work. It also keeps data reliable.

The standard size of 96 well plates is vital in lab equipment design. These plates have a precise size. This makes them fit well with many scientific tools.

Well Volume Specifications

Sample well depth and volume are important in microplate design. Most 96 well plates can hold:

- 0.1 mL to 0.3 mL per well

- They meet different research needs

- They support various experiments

Overall Plate Dimensions

Microplate making needs to be precise. The standard sizes are:

- Length: 127.76 mm ± 0.5 mm

- Width: 85.48 mm ± 0.5 mm

- Height: 14.35 mm ± 0.76 mm

Well Shape and Structure

96 well plates come in different shapes for specific research needs. The bottom types include:

- U-Bottom: 10.85 mm depth

- V-Bottom: 11.65 mm depth

- F-Bottom: 10.65 mm depth

- C-Bottom: 10.85 mm depth

“Precision in microplate design enables breakthrough scientific discoveries.” – Laboratory Research Institute

The 8×12 well array in 96 well plates ensures consistent results. This makes 96 well plates essential in today’s research.

Materials Used in 96 Well Plates

The choice of materials for 96 well plates is key to success in the lab. Scientists need to think about how the material affects the plate’s size and shape.

Polypropylene vs. Polystyrene: Material Characteristics

Polypropylene and polystyrene are the main materials used for 96 well plates. Each has its own benefits for different lab needs.

- Polypropylene advantages:

- Inert chemical composition

- Heat-resistant properties

- Excellent for sample storage

- Polystyrene strengths:

- Superior optical clarity

- Enhanced light transmission

- Ideal for imaging and spectroscopic techniques

Coated vs. Uncoated Plate Considerations

Coatings can change the plate’s surface, improving it for certain tests.

| Coating Type | Primary Application | Key Characteristics |

|---|---|---|

| High Bind | Protein binding | Maximum protein attachment |

| Tissue Culture | Cell growth | Enhanced cell adhesion |

| No Bind | General research | Neutral surface interaction |

Impact of Material on Plate Dimensions

The material used affects the plate’s size and how it holds up. Different materials change size differently, which can mess with your results.

“The right material can make or break your scientific investigation.” – Laboratory Research Quarterly

Scientists must pick materials wisely to get the best results in their experiments.

Variability in Well Dimensions

Understanding the details of 96 well plate well dimensions is key for researchers. They need precision in their work. The making of multi-well plates involves complex steps that lead to variations in well features.

How well plates are made affects their dimensions. Studies show that many things can cause these variations:

- Material composition

- Molding techniques

- Quality control processes

- Environmental manufacturing conditions

Manufacturing Tolerance Levels

Standards for making multi-well plates are strict. The ANSI/SLAS standards give clear guidelines on what’s allowed:

| Dimension | Specification | Tolerance |

|---|---|---|

| Plate Length | 127.76 mm | ± 0.5 mm |

| Plate Width | 85.48 mm | ± 0.5 mm |

Custom Designs and Dimensional Factors

Researchers might find small but important differences in 96 well plate well dimensions. Things that can affect well size include:

- Polymer shrinkage during cooling

- Precision of injection molding equipment

- Specific material properties

- Manufacturing batch consistency

“Precision in well dimensions can significantly impact experimental reproducibility and data reliability.” – Laboratory Research Consortium

Choosing the right 96 well plate is important. It’s about understanding these small differences to get the best results from your experiments.

Impact of Dimensions on Experiment Design

It’s key for researchers to grasp how sample well depth affects their work. The exact size of a 96-well plate can change the results of experiments. It impacts everything from how much sample you can use to how chemicals mix.

Effect on Sample Volume

The depth of sample wells is vital for how much sample you can use and how precise your results are. It’s important to think about well size to get the best results. This includes:

- Liquid handling capabilities

- Minimal evaporation risks

- Consistent experimental reproducibility

Considerations for Reagents

Well depth affects how chemicals interact and how accurate your results are. Shallow wells might not hold enough for some reactions. But deeper wells offer more room for different experiments.

Implications for High-Throughput Screening

High-throughput screening plates need to be made with care to work well. The Society for Biomolecular Screening’s 1998 efforts helped standardize plate sizes. This has been crucial for consistent research.

Optimal well dimensions can reduce reagent consumption by up to 75% compared to traditional screening methods.

| Well Characteristic | Standard Specification | Impact on Screening |

|---|---|---|

| Well Depth | 10.4 – 11.2 mm | Enables consistent volume management |

| Center-to-Center Distance | 9 mm | Supports precise automated handling |

| Plate Dimensions | 128 mm x 85 mm | Ensures equipment compatibility |

Knowing these details helps researchers make their high-throughput screening plates better. This leads to more efficient and accurate experiments.

Compatibility with Laboratory Equipment

Microplate specifications are key for working well with lab tools. The size of the microplate matters a lot. It affects how well these plates work with different lab equipment.

Labs need standard sizes for the best results. Knowing how 96-well plates fit with various tools is vital. This knowledge helps researchers and lab workers a lot.

Centrifuges and Shakers

Today’s centrifuges and shakers fit standard microplates well. They have special features like:

- Universal plate holders for different sizes

- Exact balance for steady rotation

- Chambers that control temperature for sensitive tests

Pipetting Systems

Pipetting systems need to match the microplate size for precise sample moving. Important things to consider are:

- Exact tip placement with well centers

- Auto-calibration for different plates

- Ability to handle many samples at once

Temperature Control Devices

Experiments that need exact temperature need plates that fit perfectly. Modern devices like thermal cyclers and incubators have:

- Adjustable heating for various plate sizes

- Even heat in all wells

- Customizable temperature settings

| Equipment Type | Compatibility Requirements | Key Performance Indicators |

|---|---|---|

| Centrifuges | Standard 96-well plate dimensions | Balanced rotation, minimal vibration |

| Pipetting Systems | Precise well positioning | Accurate volume transfer, minimal cross-contamination |

| Thermal Devices | Uniform heating capabilities | Consistent temperature distribution |

Standardization is the key to efficient laboratory workflow and reproducible scientific results.

Researchers must carefully select microplates that meet the specific requirements of their laboratory equipment to ensure optimal experimental outcomes.

Selecting the Right 96 Well Plate

Choosing the right 96 well plate is key for good scientific results. Researchers need to look at many factors to get the best results.

Critical Factors to Consider

When picking a 96 well plate, several important things matter:

- 96 well plate well dimensions matching experimental requirements

- Well volume capacity for specific research protocols

- Material compatibility with research conditions

- Optical clarity for specialized detection methods

- Temperature and chemical resistance

Recommended Brands and Products

Many makers make top-notch 96 well plates. Greiner Bio-One is a leader with over 40 years of making them. They have many options for different research needs.

*”Selecting the right microplate is as critical as the experiment itself.”* – Laboratory Research Standards

Best Practices for Usage

To use 96 well plates well, pay attention to these tips:

- Verify well dimensions before experiment

- Check material properties

- Confirm instrument compatibility

- Use appropriate handling techniques

- Store plates under recommended conditions

Knowing standard plate specs, like the SLAS footprint of 127.76 mm x 85.48 mm, helps keep experiments consistent.

Preparing for Experiments Using 96 Well Plates

Working with microplates for experiments needs careful planning and precise steps. High-throughput screening plates require attention to detail for reliable results.

Calibration and Standardization Protocols

Researchers must set up consistent calibration methods for 96 well plates. Cell density is key to success. Important standardization points include:

- Cell density adjustment between 5–25 x 10^4 cells/mL

- Plating doses of 200 µL with 10,000–50,000 cells per well

- Consistent incubation conditions at 37°C

Sample Preparation Techniques

For high-throughput screening plates, sample preparation is crucial:

- Adjust cell density to 25–100 x 10^4 cells/mL

- Plate 200 μL of cell culture (50,000–200,000 cells)

- Incubate for 24 hours at 37°C

- Perform controlled stimulation

Data Collection and Analysis

Precise data collection needs specific microplate specs. Key steps include:

| Process | Specifications |

|---|---|

| Washing | 3 washings with 200 μL ice-cold PBS |

| Centrifugation | 300 x g for 7 minutes |

| Cell Extraction | 30 μL protease-inhibitor-supplemented buffer |

“Precision in preparation determines the quality of scientific discovery.” – Laboratory Research Principles

Researchers must focus on each step. This ensures consistent methods in experiments. Following these techniques will improve the reliability of results in high-throughput screening.

Conclusion: Importance of Understanding Well Dimensions

The world of scientific research is always changing. 96 well plate well dimensions are key to precise experiments. These multi-well plates are not just containers. They are advanced tools for quick testing and detailed analysis.

Knowing the details of 96 well plate well dimensions helps scientists pick the right tools. They can choose based on volumes from 50 μL to 200 μL and special well shapes. These microplates are where tech meets science.

Summary of Key Points

Modern research needs to be precise. Multi-well plates have changed labs by letting them test many samples at once. This makes work faster and more efficient.

The right choice of materials, volumes, and shapes is crucial. It affects the results and how reliable the data is.

Future Trends in 96 Well Plate Design

New technologies will keep improving plate making. We might see less contamination, better materials, and more special shapes. Scientists will have even better tools for their work.

Final Thoughts on Optimal Usage

Success in labs comes from paying close attention to details. Knowing about 96 well plate well dimensions helps scientists. They can make their experiments better, reduce mistakes, and discover more.

FAQ

What are the standard dimensions of a 96 well plate?

A standard 96 well plate is 127.76 mm x 85.48 mm. Each well is about 6.40 mm x 6.40 mm. The depth can be between 10.16 mm to 14.22 mm, depending on the design.

What is the typical well volume for a 96 well plate?

The well volume is usually 200 µL to 360 µL. Most use around 300 µL per well. The exact volume needed varies by experiment.

How do material choices affect 96 well plate performance?

Polypropylene and polystyrene are common materials. Polypropylene is good for PCR because it’s chemically resistant. Polystyrene is better for cell culture and fluorescence assays because it’s clear. The material affects how samples interact and the results of experiments.

What factors should be considered when selecting a 96 well plate?

When choosing a plate, consider the well volume, material, surface treatment, sterility, and optical properties. Also, think about temperature resistance and the specific needs of your experiment.

How do well dimensions impact experimental results?

Well dimensions affect sample volume, mixing, and heat transfer. They also impact how well experiments can be repeated. The right size ensures consistent handling and accurate data.

Are 96 well plates compatible with all laboratory equipment?

Most lab equipment fits standard 96 well plates. But, always check if your equipment works with the plate size before starting your experiment.

What are the common manufacturing tolerance levels for well dimensions?

Manufacturers usually stick to ±2-5% tolerance for well sizes. High-quality plates might have even tighter tolerances for consistent results.

How do surface treatments affect 96 well plate performance?

Surface treatments change how cells and proteins interact with the plate. There are treatments for cell culture, ELISA, and more. They help with specific experiments.

What are the primary applications of 96 well plates?

96 well plates are used in many fields. They’re key in high-throughput screening, molecular biology, and drug discovery. They’re also used in genomics, proteomics, and diagnostics.

How should 96 well plates be stored and handled?

Store plates in sealed containers to keep them clean. Keep them away from dust and at the right temperature. Handle them carefully to avoid damage.

Pingback: What is the surface area per well of a 96 - well plate?

Pingback: What is the size of a 96 well plate?

Pingback: What is the area of a 96 well plate?

Pingback: What are the dimensions of a 96 well plate?

Pingback: Understanding 96 Well Plate Volume for Lab Applications

Pingback: Understanding the 96 Well Plate Diagram for Lab Research