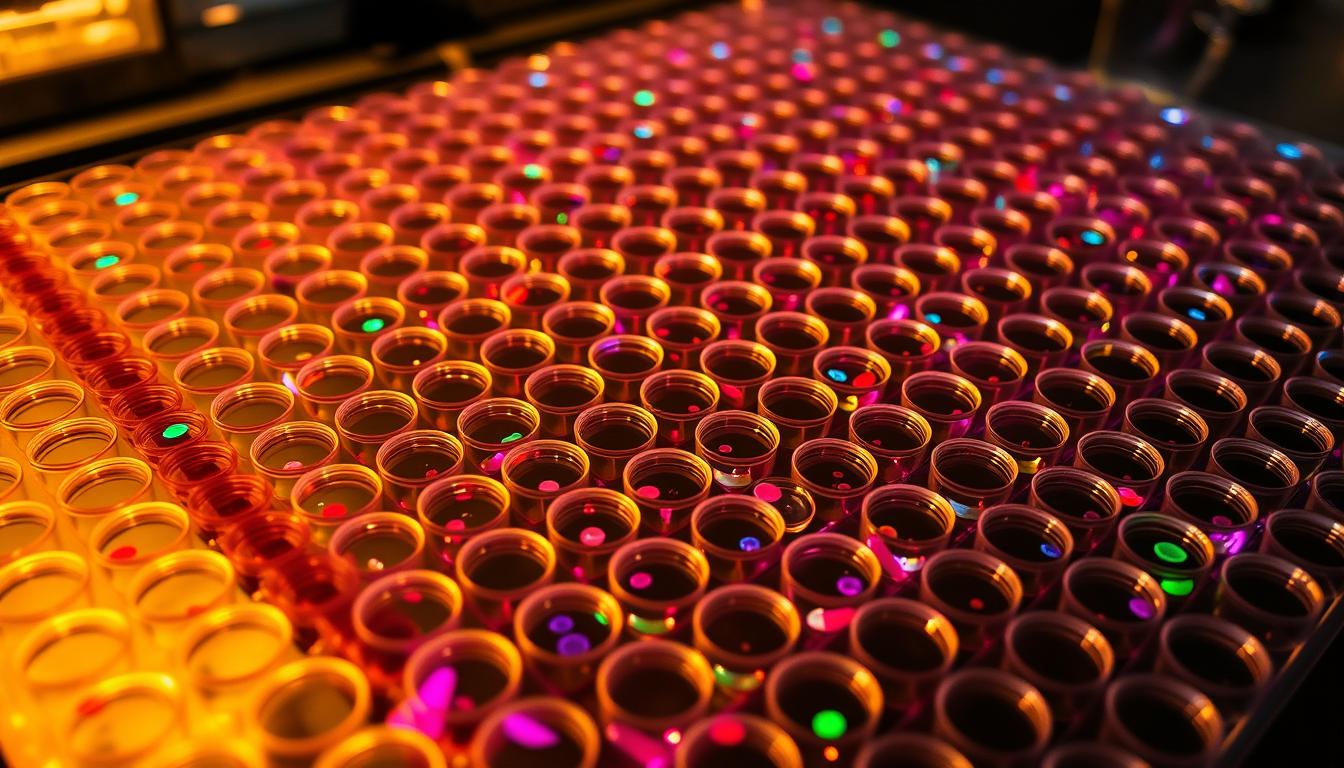

In today’s fast-paced laboratories, efficiency and accuracy are non-negotiable. High-density microplates have become indispensable tools, enabling scientists to conduct multiple tests simultaneously. These standardized formats streamline workflows, ensuring reproducibility in cell-based studies and diagnostics.

Automation compatibility and material quality play a crucial role in assay performance. By reducing reagent consumption, these plates cut costs while maintaining sensitivity. Their design directly impacts experimental outcomes, making them vital for drug discovery and molecular biology.

Key Takeaways

- Standardized formats enhance reproducibility in biological research.

- High-density plates reduce reagent use and lower costs.

- Automation compatibility improves workflow efficiency.

- Material quality ensures reliable experimental results.

- Optimized designs boost assay sensitivity and performance.

Introduction to 96 Well Plates

Standardized microplates have transformed biological research by enabling parallel testing. Their design traces back to the 1960s, when the Society for Biomolecular Sciences pioneered uniformity in lab tools. Today, these plates adhere to ANSI/SBS dimensional specifications, ensuring compatibility with automated systems worldwide.

Common applications include cell proliferation and cytotoxicity studies. Researchers favor them over traditional vessels because they process multiple samples simultaneously. This efficiency reduces reagent use and accelerates data production.

Surface treatments like oxygen plasma enhance cell adhesion, critical for tissue growth. Sterility standards are strict, supporting long-term cultures. Capacity varies by geometry, typically holding 200–400µL per well.

Key advantages include:

- Precision alignment with robotic handlers

- Optimized well spacing for consistent results

- Versatile treatments for diverse cell types

Key Applications of 96 Well Plates in Research

High-throughput screening has revolutionized how scientists analyze complex cellular interactions. These plates excel in protein binding assays, where precision impacts experimental outcomes. Fluorescence-based techniques, like FRET, reveal real-time molecular dynamics with unmatched sensitivity.

ELISA workflows thrive here, quantifying antibody-antigen binding efficiently. Luminescent reporter assays, another staple, track gene expression patterns across hundreds of samples. Consistent spacing ensures reliable results, whether for drug toxicity or 3D tumor models.

Key uses include:

- Drug discovery: High-content screening identifies bioactive compounds faster.

- Cytotoxicity tests: Fluorescence markers assess cell viability under stress.

- Kinetic studies: Continuous optical monitoring captures reaction trends.

Compatibility with automated plate readers allows multiplexed detection. This versatility makes them indispensable for labs prioritizing speed and accuracy.

Types of 96 Well Plates for Specialized Assays

Different well geometries serve unique purposes in biological research. Choosing the right design ensures precise measurements and minimizes cross-contamination. Three primary configurations dominate labs: flat, round, and conical bottom plates.

Flat Bottom vs. Round Bottom vs. Conical Bottom

Flat bottom plates excel in absorbance readings and adherent cell cultures. Their even surface simplifies optical analysis. Round (U-bottom) variants are ideal for suspension cultures, promoting uniform cell distribution.

Conical (V-bottom) designs concentrate pellets during centrifugation. This suits ELISA washes or bead-based assays. Matching the shape to the assay type prevents data skewing.

Clear, Black, and White Polystyrene Options

Transparent plates suit colorimetric tests, while black variants reduce background noise in fluorescence. White plates enhance luminescence signals for high-sensitivity detection. Material opacity directly affects signal-to-noise ratios.

Glass Bottom Plates for High-Resolution Imaging

These plates feature #1.5H cover glass (0.170±0.005mm) for crisp microscopy. Gamma-sterilized options maintain sterility for live-cell imaging. Surface treatments like collagen improve adherence during time-lapse studies.

Key advantages include:

- Numerical aperture matching for oil immersion objectives

- Thermal stability during prolonged experiments

- ANSI/SBS compliance for automated stage order

Material Quality and Sterility Standards

Sterility and material integrity define reliability in modern lab consumables. Even minor contaminants can skew results, making adherence to stringent standards non-negotiable. From polymer purity to packaging protocols, every detail ensures assay reproducibility.

USP Class VI Virgin Polystyrene

High-quality plates use USP Class VI virgin polystyrene, free from additives that could leach into samples. This grade passes rigorous biological reactivity tests, ensuring compatibility with sensitive cell cultures. Its optical clarity also enhances absorbance readings for precise data.

Gamma-Sterilized and Aseptic Options

Gamma irradiation guarantees sterility without residual chemicals, ideal for critical applications. Alternatively, *aseptic manufacturing* in ISO-classified cleanrooms prevents contamination during production. Individually wrapped packs maintain sterility until use, while bulk cases suit high-volume labs.

Key quality controls include:

- Sterilization validation: Dose mapping confirms uniform microbial inactivation.

- Particulate checks: Filters detect debris in sealed packs.

- Seal integrity tests: Dye penetration assays verify barrier effectiveness.

Non-Treated vs. Treated Surface 96 Well Plates

Surface treatments in microplates significantly influence cell behavior and assay outcomes. Non-treated polystyrene plates, with hydrophobic surfaces, excel in suspension cultures by minimizing unwanted adhesion. In contrast, tissue-culture (TC)-treated variants enhance attachment for adherent cell cultures through deliberate modifications.

Plasma treatment alters surface energy, converting hydrophobic polystyrene to hydrophilic. This boosts cell adherence and reduces non-specific protein binding. Covalent coatings like collagen or poly-L-lysine further mimic extracellular matrices, ideal for stem cell or primary culture work.

Key differences include:

- Low-binding surfaces: Prevent protein adsorption, yielding cleaner backgrounds for spheroid imaging.

- UV ozone treatment: Enhances wettability for uniform reagent distribution.

- Stability: Modified surfaces retain properties under standard storage conditions.

Studies show treated plates produce tighter cancer spheroids with fewer satellite colonies. Their optimized surface chemistry supports automated analysis, crucial for high-throughput workflows.

Features of High-Performance 96 Well Plates

Precision-engineered microplates elevate experimental accuracy with advanced features. These designs address critical needs in modern research, from sample tracking to minimizing environmental interference. Below are key innovations that enhance reliability in high-throughput workflows.

Lid and Barcoding Options

Automation-compatible lids ensure secure sealing, reducing evaporation during long assays. Alphanumeric barcodes enable error-free sample identification, crucial for large-scale studies. Options include:

- Gas-permeable membranes: Maintain CO2 levels for live-cell imaging.

- Stackable designs: Optimize incubator space without compromising sterility.

- QR codes: Integrate with LIMS for seamless data tracking.

| Lid Type | Best For | Key Benefit |

|---|---|---|

| Flat | Short-term assays | Easy robotic handling |

| Domed | Long-term cultures | Prevents condensation |

| Vented | Hypoxic conditions | Balances gas exchange |

Low Evaporation and Ultra-Low Attachment Designs

Hydrogel coatings inhibit protein attachment, ideal for spheroid cultures. Edge-effect minimization ensures uniform reagent distribution across all wells. These plates excel in:

- 3D cell models: Stability under hypoxic conditions.

- Luminescence assays: High optical clarity reduces signal noise.

- Overlay media techniques: Compatibility with viscous solutions.

Advanced surface topology, verified via AFM, guarantees consistency in research outcomes. Evaporation rates remain below 2% even at 37°C, critical for kinetic studies.

Technical Specifications and Dimensions

Precision measurements in lab tools dictate experimental success. Microplates adhere to strict dimensional standards, ensuring compatibility with automated systems. The standard size—127.76 mm × 85.48 mm (±0.25 mm)—fits robotic handlers seamlessly.

Well spacing (9.02 mm center-to-center) minimizes cross-contamination. Gravimetric testing verifies volumes (40–280 µL per well), critical for reproducibility. For detailed tolerances, see ANSI/SBS-compliant plates.

Key mechanical specs include:

- Height compliance: 14.35 mm ±0.76 mm for stackable storage.

- Flatness: ≤0.25 mm deviation for automated microscopy.

- Centrifuge ratings: Withstands 3,000×g for pellet concentration.

Thermal expansion coefficients (0.06 mm/°C) ensure stability during cycling. Bulk case options suit high-throughput labs, while individual packs maintain sterility.

Polypropylene variants resist chemicals, ideal for PCR workflows. RNase/DNase-free certification guarantees uncontaminated results. These plate features are non-negotiable for sensitive assays.

Choosing the Right 96 Well Plate for Your Research

Modern laboratories require precise plate selection to match assay requirements and detection methods. The wrong choice can compromise cell viability or skew results. Key factors include optical properties, surface chemistry, and automation compatibility.

Flat-bottom designs dominate absorbance readings, while round wells suit suspension cultures. For luminescence, white plates amplify signals, and black variants reduce fluorescence bleed-through. Consider these detection modality matches:

| Assay Type | Optimal Plate | Critical Feature |

|---|---|---|

| ELISA | High-binding polystyrene | Uniform protein adsorption |

| FRET | Black polystyrene | Low autofluorescence |

| 3D cell models | Ultra-low attachment | Hydrogel coating |

| PCR | Polypropylene | Thermal stability |

Throughput needs dictate plate density. High-content screening benefits from 384-well formats, but 96-well balances volume needs with robotic handling. Key trade-offs:

- Sample volume: 40-280µL range affects reagent costs

- Edge effects: Evaporation-resistant designs maintain uniformity

- Statistical power: More replicates improve data confidence

Chemical resistance matters for harsh solvents. Polypropylene handles organics better than polystyrene. Always validate plates with equipment like GloMax® readers. Automated systems need ANSI/SBS compliance for precise positioning.

Specialty coatings add cost but prevent cell detachment in long cultures. Plasma-treated surfaces outperform non-treated for adherent lines. Weigh these factors against budget constraints for reproducible results.

Industry Standards and Compliance

Strict industry standards govern every stage of microplate production. These protocols ensure quality and safety across global labs. From raw materials to final packaging, compliance minimizes variability in research outcomes.

ISO 9001 certification validates consistent manufacturing processes. It covers design controls, risk management, and corrective actions. Labs prioritize suppliers with this credential for reliable production workflows.

In the U.S., 21 CFR Part 11 governs electronic records and signatures. This rule ensures data integrity for FDA submissions. Features like audit trails and access controls maintain quality in automated systems.

| Standard | Region | Key Requirement |

|---|---|---|

| CE Marking | Europe | Meets EU safety/health directives |

| REACH | Global | Chemical safety documentation |

| USP <661> | U.S. | Plastic container leachability testing |

ASTM standards verify mechanical properties like tensile strength. GMP documentation tracks every order for traceability. Together, these frameworks create a robust quality ecosystem.

ANSI/SLAS 1-2004 ensures precise footprint dimensions. This guarantees robotic handlers align plates in correct order. Such attention to detail prevents costly automation errors.

Conclusion

Microplate technology continues to evolve, shaping the future of biological research. AI-driven platforms now automate data analysis, boosting efficiency in high-throughput workflows. Sustainability efforts push for eco-friendly products, reducing lab waste without compromising quality.

Custom plate designs meet specialized needs, from 3D cell cultures to sensitive luminescence assays. Supplier support ensures proper validation for critical applications. Balancing performance with total cost remains key for labs scaling their operations.

For reliable results, choose high-quality plates that align with your assay goals. Precision engineering and strict compliance guarantee reproducible outcomes in modern laboratories.

FAQ

What are the main differences between flat, round, and conical bottom plates?

Flat bottom plates ensure uniform cell attachment and are ideal for absorbance readings. Round bottom plates suit suspension cultures, while conical bottoms are optimized for pelleting cells during centrifugation.

How do clear, black, and white polystyrene plates differ in applications?

Clear polystyrene is best for general cell culture and microscopy. Black plates minimize background noise in fluorescence assays, while white plates enhance luminescence signal detection.

Why choose glass bottom plates for imaging studies?

Glass provides superior optical clarity for high-resolution microscopy, reducing distortion compared to plastic. It’s essential for techniques like confocal or TIRF imaging.

What does USP Class VI virgin polystyrene mean for plate quality?

This certification ensures the material is free from contaminants, non-cytotoxic, and compliant with strict biological safety standards for cell-based research.

When should researchers use gamma-sterilized plates?

Gamma sterilization guarantees sterility without chemical residues, making these plates ideal for sensitive assays or long-term cell culture where contamination risks must be minimized.

What advantages do treated surface plates offer over non-treated ones?

Treated surfaces (e.g., Nunclon Delta or collagen-coated) enhance cell adhesion and growth, while non-treated plates are better for suspension cultures or preventing attachment.

How do low-evaporation designs improve assay reliability?

These plates reduce volume loss during incubation, maintaining consistent reagent concentrations—critical for kinetic studies or prolonged experiments.

What plate specifications are vital for automated systems?

ANSI/SBS-compliant dimensions, barcoding options, and compatibility with robotic handlers ensure seamless integration into high-throughput workflows.

Which plate type is best for ELISA or protein binding assays?

High-binding polystyrene plates maximize protein adsorption, while medium- or low-binding surfaces are preferred for reducing non-specific interactions.

How do I verify compliance with industry standards?

Look for certifications like ISO 13485 or CE marking, which validate manufacturing quality and adherence to regulatory requirements for diagnostic or clinical use.

Leave a Comment

Your email address will not be published. Required fields are marked *